What is VOC?

A VOC is a Verification of Competency

Did you know that it is up to the employer to ensure staff skills are up to date and maintained – just having a licence when you employed them is not enough?

Your staff have their licences, but what have you done to ensure they still know what they are doing?

How many of your workers got their licences ‘years ago’ and have never had their skills tested or competency assessed?

No longer is just holding a ticket or qualification enough for an employer to believe an individual is competent. If an accident occurs, what evidence do you have that you have checked whether your staff are up to the job?

Verification of Competency (VOC) is a method of assessment that assists employers to meet Work Health and Safety (WHS) requirements and ensure staff are competent to operate equipment or perform a task. New national WHS harmonisation laws, effective January 2012, bring greater importance to employers due diligence and obligation to ensure an individual has “current industry competency”. Assessing for Verification of Competency enables businesses to confirm that their employees are competent in their skills and using equipment.

VOC assessments are used to ensure staff can operate equipment in complete safety. If they can do so according to requirements of the work site it also means substantial savings for their employer. It is better that operators are assessed be competent beforehand rather than injuring themselves, a co-worker or damaging machinery due to poor skills.

VOC’s provide an opportunity to highlight any bad habits that may have presented themselves over time. The assessment is completed in your worksite, at a time convenient to you, and is designed to have a minimal impact on your operation. There is NO NEED to sacrifice large groups of workers for lengthy sessions that interrupt your work schedule. Our assessments take place on the job, and are based on visual observational and verbal questioning, one person at a time, as they carry out their normal work day.

It is commonly used in many industries for pre-employment checks, contractual arrangements or site requirements.

Verification of Competency enforcement is new for industry and is subject to interpretation. HPA Training have been working with major industry and business since 2001 including Thiess, Leightons, John Holland to name but a few, and have developed a formal process that allows for thorough assessment of VOC candidates whilst offering flexibility to meet client needs with minimal impact to productivity.

Our assessors are industry experts holding all relevant qualifications combined with many years of experience.

What is the VOC Process?

Verification of Competency Assessments are completed at the worksite or can be conducted at your base premises or at an arranged venue, at a time convenient to you, and are designed to have minimal impact on your operation. There is NO NEED to sacrifice large groups of workers for lengthy sessions that interrupt your work schedule.

Our assessments are based on visual observational and verbal questioning as well as written assessment, one person at a time, as they carry out their normal work day duties. On completion of the VOC, the employer is provided with an assessment summary to be kept with employee training records, identifying the employee as being competent, or if unsuccessful, any areas which require attention and suggested methods of meeting the gaps discovered during the VOC. This assessment record can form the basis for your internal training plan and records as well as evidence of employer actions and responsibility in meeting WHS requirements.

REQUEST REPLACEMENT CARDS/CERTIFICATES HERE

REQUEST REPLACEMENT CARDS/CERTIFICATES HERE

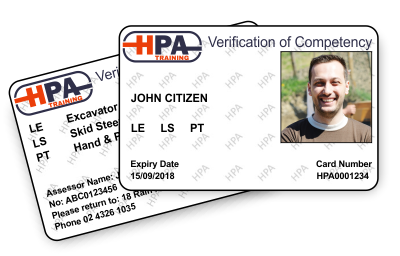

Each successful candidate will be issued with a HPA Training photo ID card displaying their successful competency in disciplines assessed once the assessment invoice has been satisfied. These photo cards and their associated records are nationally recognised and are valid for a period of two (2) years from assessment. Many of the major building contractors performing Principal Contractor roles are now insisting on the displaying of these assessment cards prior to allowing sub contractors on site.

In circumstances requiring expedience and immediate entry to a Principal Contractor’s site, a list of newly assessed and competent candidates will be provided to the Principal Contractor when the assessments are completed. This is an interim measure only until the assessment has been paid for and the card issued. Payment will be expected to be made to HPA Training by close of business (EDST) on the assessment day.

NO PAYMENT – NO PHOTO CARD – PRINCIPAL CONTRACTOR/PCBU WILL BE NOTIFIED = NO SITE ADMISSION

VOC assessment takes between 1–3 hours and will depend on type of plant and/or requirement of employer/site.

Which industry disciplines can HPA Training assess?

HPA Training conduct VOC’s for both High Risk Work and Plant as well as most other construction disciplines. If you already hold a licence or competency in either of these areas, we can conduct a VOC for the specific licence or model of equipment.

By implementing this VOC process it will assist Employers and Principal Contractors in complying with the WH&S Act 2011. The WH&S Act states, an Employer and/or Principal Contractor is responsible for an employee to be trained and competent on every item of Equipment, Plant and for High Risk Work they carry out.

Once you are competent in a practical and theory assessment, and have paid in full for your VOC, HPA Training will issue a VOC Photo ID Card which will be stamped with each specific competency. They are accepted by all major industries and are valid from the time of testing for a period of two (2) years.

HPA Training High Risk VOC’s

| CV | Vehicle loading crane | RI | Rigging intermediate |

| CN | Non-Slewing Crane | RA | Rigging advanced |

| C2 | Slewing mobile crane ^20 tonne | SB | Scaffolding basic |

| C6 | Slewing mobile crane ^60 tonne | SI | Scaffolding intermediate |

| C1 | Slewing mobile crane ^100 tonne | SA | Scaffolding advanced |

| CO | Open crane | WP>11M | Elevated work platform |

| CT | Tower crane | LF | Forklift |

| CD | Derrick crane | HP | Personnel and materials hoist |

| DG | Dogging | CS | Self-erecting crane |

| RB | Rigging basic | | |

HPA Training Not High Risk VOC’s

| AG | Agitator | LU | Use of ladders |

| AHT | Articulated haul truck | MC | Mobile chipper |

| AR | Rock Anchoring | MH | Manual handling |

| AW | Arc Welding | OC | Oxy/accet. cutting |

| BA | Advanced boiler operator | OS | Operation supervisor |

| BB | Basic boiler operator | OW | Oxy/accet. welding |

| BHT | Belly Dump Haul Truck | PB | Concrete boom pump |

| BI | Intermediate boiler operator | PC | Concrete pumping |

| BP | Bored piers | PD | Pile driving |

| BPT | Bar Post Tensioning | PE | Small plant & equipment |

| BS | Bituminous Surfacing | PJ | Pallet jack |

| CB | Bridge Gantry Crane | PR | Piling rig |

| CC | Cut & Core concrete | PRO | Profiler |

| CDR | Core Drilling Rig | PT | Hand & power tools |

| CF | Finish Concrete | PV | Paver |

| CG | Gantry Crane (remote control) | RHT | Rigid haul truck |

| CH | Chainsaw | RL | Roller |

| CL | Container Side Lifter | RLC | Compactor |

| CP | Portal Crane | RS | Road (pavement) sweeper |

| CR | Crusher | RSC | Restricted height scaffold |

| CSP | Confined spaces | SC | Scraper |

| DD | Directional drilling | SG | Stump grinder |

| DHT | Dumpy Haul Truck | SH | Shredder |

| DL | Dragline | SHB | Shuttle buggy |

| DR | Drilling rig | SHC | Shot-Crete |

| DS | Demolition saw | SD | Site dumper |

| DT | Drott | SL | Motorised slasher |

| DZ | Dozer | SM | Surface mining |

| ES | Reciprocating steam operator | SP | Working safely near electrical apparatus (Spotter) |

| EPT | Explosive power tools | SPM | Specialized machinery |

| FS | Flora shredder/chipper | ST | Sucker truck |

| FW | Formwork | TC | Traffic controller |

| GM | Glazing machine | TM | Trenching machine |

| GR | Grader | TO | Turbine operator |

| HM | Materials hoist | TR | Tractor |

| HT | Haul/dump truck | TSH | Telescopic handler |

| KCM | Kerb & channel machine | VP | Vacuum pump truck |

| LB | Backhoe | WC | Water cart |

| LE | Excavator | WCH | Wood chipper |

| LECR | Excavator in crane mode | WH | Work safely at heights |

| LOS | Lifting operational supervisor | WIN | Winch |

| LFS | Forklift specialised | WP<11M | Work platform under 11M |

| TM | Trenching machine | SL | Scissor lift |

| LL | Front end loader | BL | Boom lift |

| LO | Order picking forklift truck | VL | Vertical lift |

| LP | Identify, locate & protect (Spotter) | TL | Trailer lift |

| LS | Skid steer | TM | Truck mounted |